What is a circular supply chain and how do we get there?

Let’s be honest, a lot of the ideas and theories about a circular economy are just that, ideas and theories, but even though we are at the beginning of a very long journey, there’s been great progress and this is the path we need to be on. The path we are on currently, we already know it leads to a dead end.

Fast fashion is killing us and our planet, Synthetic materials like polyester require an estimated 342 million barrels of oil every year. The production process of fabric dying requires 43 million tonnes of toxic chemicals a year.

A shirt requires 2700 litres of water to make, a pair of jeans, 10,000 litres of water. $3.3 billion of hazardous pesticides are sprayed on conventional cotton crops each year.

Chemicals like Aldicarb, a powerful nerve agent, and Endosulfan are linked to comas, seizures, and even death.

These same chemicals can cause sterility, spontaneous abortion, still borns, and cancer. Chemical runoff from cotton fields pollutes ecosystems such as rivers and lakes and can poison our fish.

“We can not save our people and planet without achieving a circular economy.”

Micro-plastics shed from synthetic clothing can find their way into our ocean from various sources such as the degradation of marine plastic debris, drainage systems, spills from manufacturing sites, and more.

Marine creatures like birds, fish, mammals, and plants, consume these micro-plastics and face both chemical and physical repercussions.

This can result in decreased food consumption, suffocation, altered behavior, and genetic modifications.

Besides being consumed through seafood, humans can also breathe in microplastics from the atmosphere, take them in through drinking water, and absorb them via skin contact. Micro-plastics have been detected in several human organs and astonishingly, even in the placentas of newborns. That’s terrifying!

We have a long road ahead of us before we can say as a society that we’ve achieved circularity. Let’s be clear, without a doubt, we can not save our people and planet without achieving a circular economy.

Here at Wild Unlimited we spend a lot of time talking about circular supply chains, thinking about circular supply chains, and working towards developing our own circular supply chain.

But we also realize that if you don’t work in production or manufacturing, you might not spend as much time obsessing over them as we do.

So let’s take a moment to go over what a circular supply chain is, why it’s essential for our people and planet, and how we as a company are continuing to work towards circularity, and what we need to do to make it a reality.

What exactly is a circular supply chain?

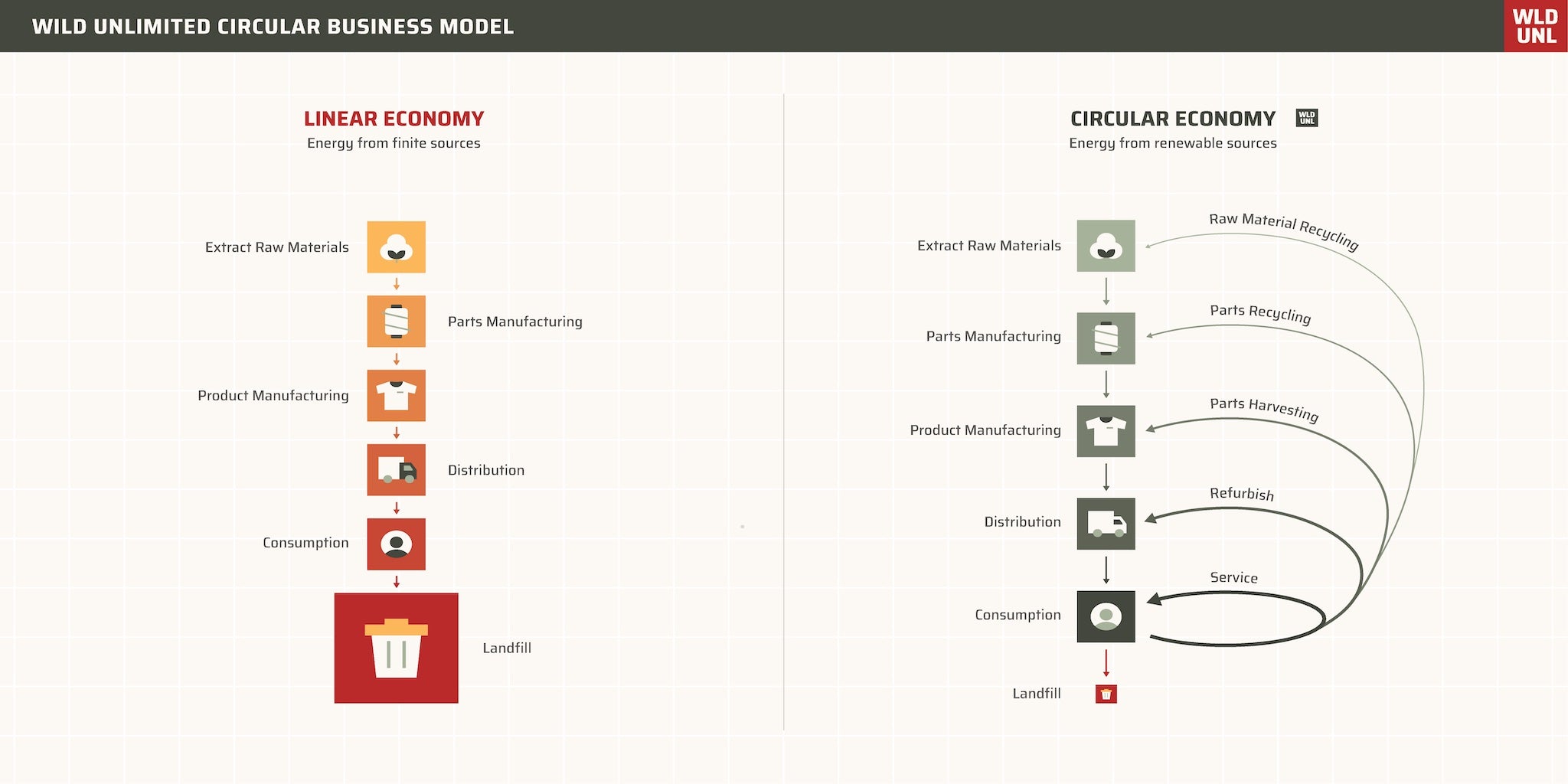

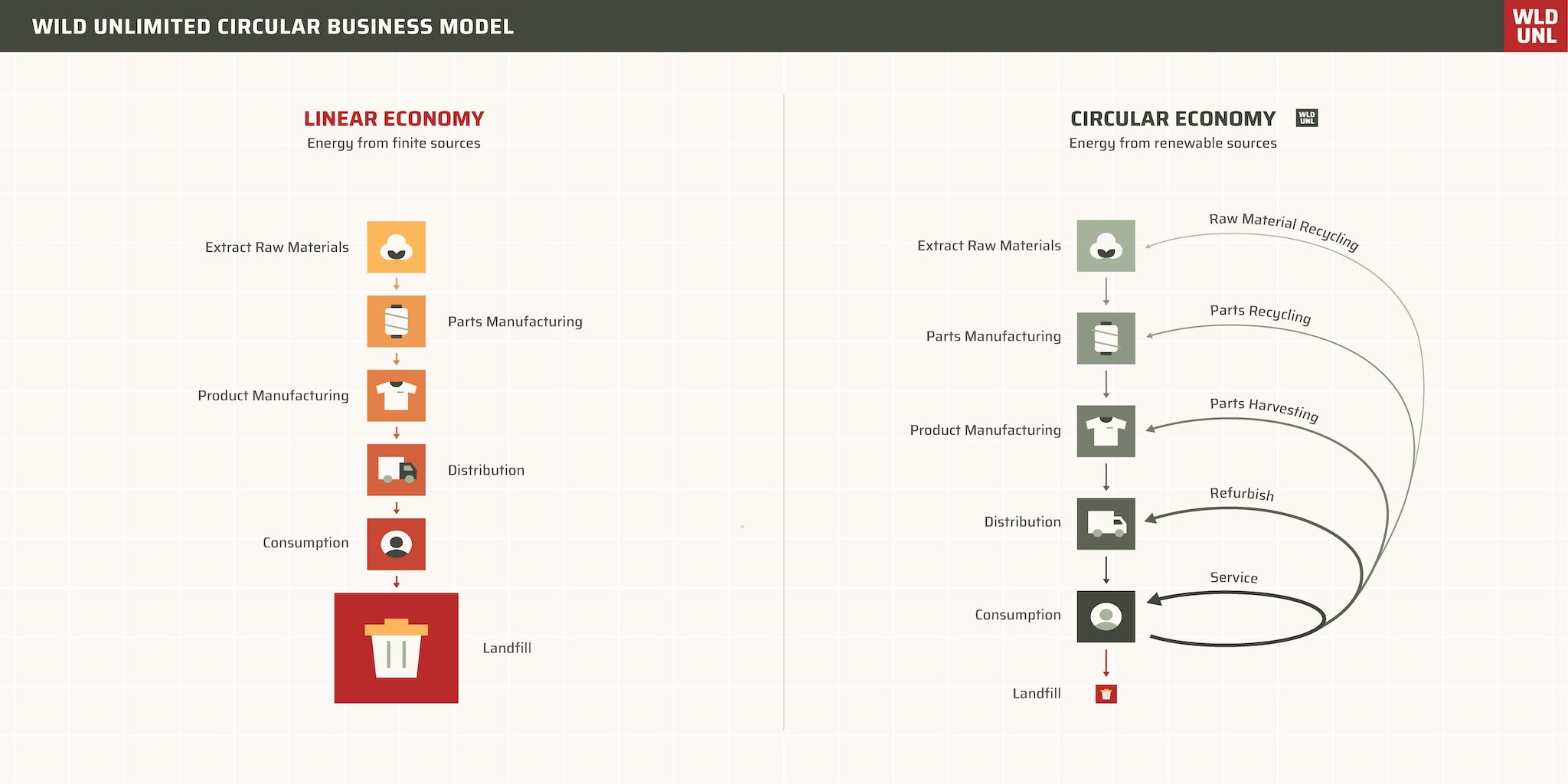

The easiest way to understand a circular supply chain is to first think about a traditional linear supply chain.

In a typical manufacturing process the chain of supplies and production only move in one, linear direction.

For example, in the fashion industry, synthetic polyester yarn made from petrochemicals is woven into fabric, that fabric gets turned into clothing, that clothing is purchased and worn for a short amount of time, and eventually it ends up in a landfill.

These synthetic materials can take up to 200 years to decompose and in the process, off-gas methane, which is worse for the environment than carbon monoxide.

This linear process repeats for the next season while the landfill gets fuller and our people, planet, and wildlife, pay the price.

The fashion industry is responsible for 8-10% of global emissions, according to the UN - that’s more than the aviation and shipping industry combined.

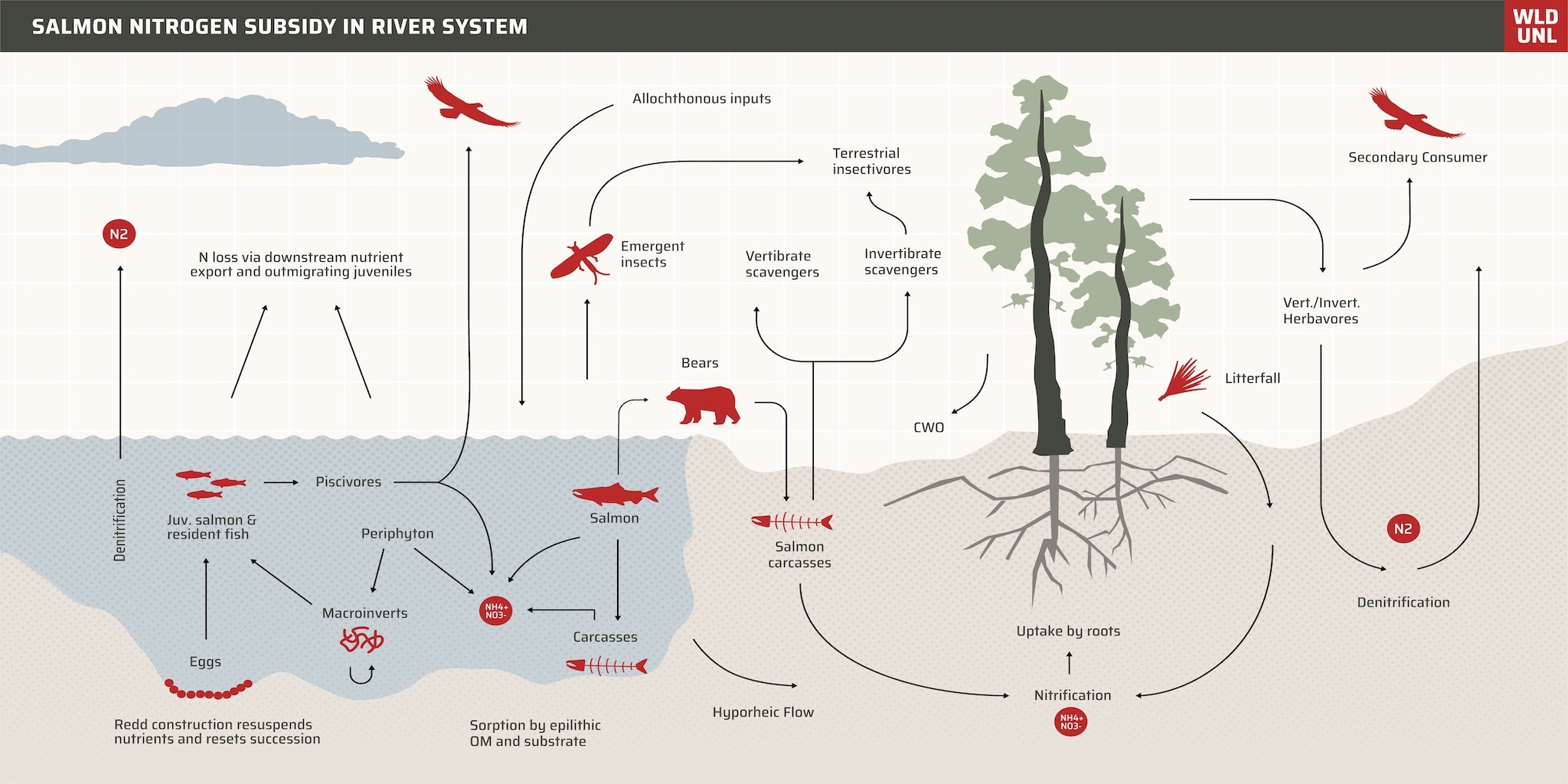

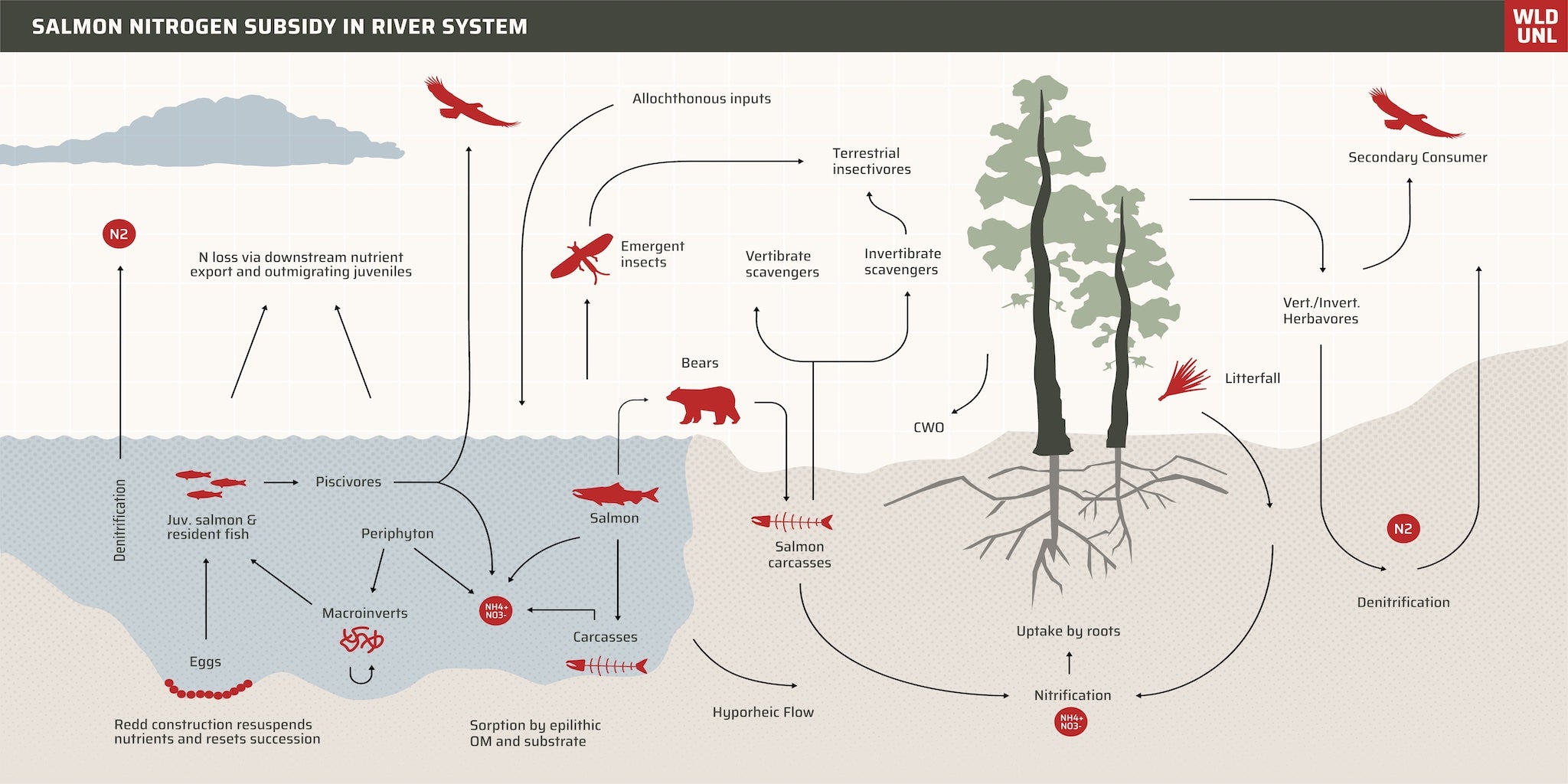

In contrast, a circular supply chain focuses on preventing waste from ending up in landfills. Think of the lifecycle of salmon. The cyclical journey of birth, growth, migration, reproduction, death, and rebirth showcases nature's inherent circularity.

The salmon lifecycle not only perpetuates the species but also nourishes both aquatic and terrestrial ecosystems in the process. In this natural circular system, nothing goes to waste.

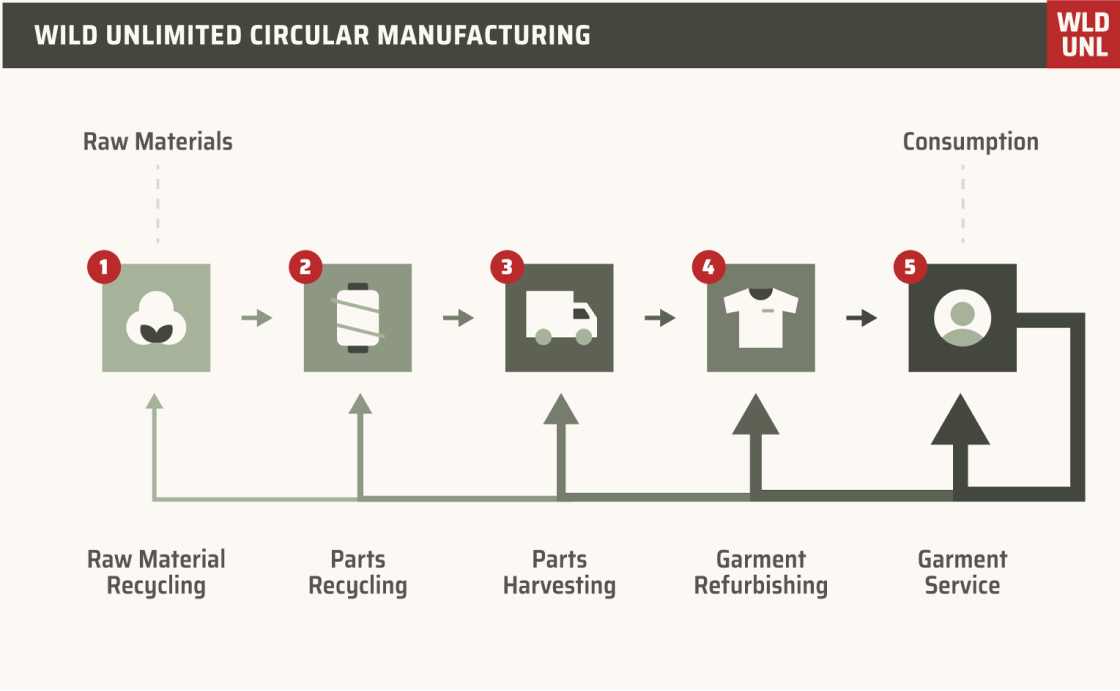

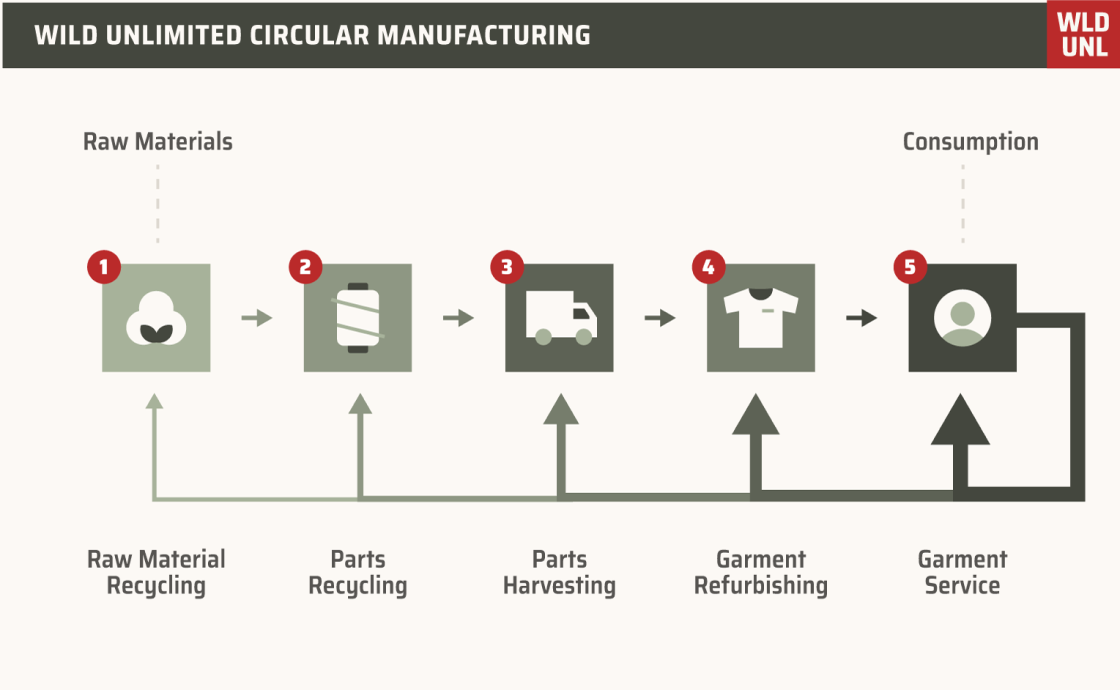

We can learn a lot from salmon and apply those learnings to garment manufacturing. At Wild Unlimited, the process we are trying to perfect is using natural and renewable materials like wool and hemp that decompose quickly, and by reducing and recycling materials at every step of the manufacturing process.

Excess raw materials like organic cotton or wool on our factory floors are turned into new garments, clothing that wears out is repaired, and gear that reaches the end of its life is re-harvested and recycled into materials that can be used to create brand new products.

“It’s hard to run a company without a planet”

By circling materials back to earlier steps of the process at each manufacturing stage a circular supply chain reduces the volume of materials needed to create new products, extends the lifecycle of products that are created, and most importantly ensures that the amount of materials that end up in our landfills is drastically, or in a perfect world completely, reduced.

Are we there yet?

It sounds like a question a kid would ask you from the back seat of a long trip to the river, but the answer also sounds like what you’d tell that kid: Not yet.

A perfectly circular supply system creates zero waste and uses no net new resources, depending entirely on reuse and recycling to sustain itself.

Unfortunately given the current state of manufacturing and resource generation, getting to that perfectly circular process is not yet achievable.

Today, manufacturing remains a complex cross-industry network, and creating a product often requires cooperation across different countries and continents with actors who have different rules, different regulations, and different priorities.

Additionally, many factories and supply chains operate on antiquated business models with razor thin profit margins, and asking them to front the cost to re-tool with new machinery and unfamiliar business practices is often met with resistance — even if it’s better in the long run for the planet (not to mention their business because, guess what? It’s hard to run a company without a planet.

Add all of that together with the fact that only a few top-tier manufacturers on the planet have even begun their journey towards circularity, and it’s easy to see why a truly circular supply chain is still out of reach.

So how do we get there?

If the status of circular manufacturing sounds a little bleak so far, allow us to share some of the apparel companies that are making significant strides towards achieving circularity.

Patagonia has implemented initiatives like the “Worn Wear” program, which encourages customers to repair and reuse products rather than discarding them.

REI’s “Opt to Act” campaign encourages customers to take individual actions to reduce their impact.

Outerknown has launched “Outerworn”, which enables customers to purchase and sell second-hand items, which can then be transformed into new products.

As a small startup brand Wild Unlimited doesn’t have quite the same resources and buying power as some of the better known names, and that makes worn wear and used garment recycling programs a little more challenging to set up — but that doesn’t mean we’re not working towards it.

By the end of 2024, we’re working to launch a second hand program for lightly used garments, as well as the ability to offer gear rental for outdoor adventurers that can’t afford our most expensive products.

Today, any customer can send their used gear back to us to have it properly recycled, or take advantage of our gear repair services.

Together all of these programs and efforts are helping to not only reduce waste, but to increase awareness and public support for circularity, which is key to getting those large, complex manufacturing networks to make the pivot we need to one day achieve a perfectly sustainable production process.

As a brand that’s on a mission to protect what’s left of our wild salmon and steelhead, and the places they live, we know we have a unique responsibility to do what we can to preserve and protect the planet.

Embracing circular practices and embedding them into our manufacturing process is a choice we’ve made because we love our planet, and we hope it’s one that you’ll support and embrace along with us.